Hollowing of Oak Beams

Oak beam casings, and hollowed oak beams are a great way to cover steels and pipes.

Whether you have a steel fitted in your house that needs covering, some pipes down a wall that you don’t want to see, or even a fireplace lintel that you want to freshen up, oak beams are a great way of covering. At Oakfield Beams & Framing we have perfected the art….. So how do we do it?

Getting ready with the first few cuts

The cuts have finished, now the knocking out of the oak happens

We start by taking measurements of what needs covering. We then select an oak beam that is a suitable size to make sure we leave enough oak on the sides and the bottom to keep the oak beams strong.

Cuts are made along the length of the beam with a chainsaw to the depth required. We then cross cut the beam at approximately 200mm each cut to give a hatched look and lots of little bits of oak.

Knocking out the sections makes for great logs!

The hard work starts next. With a hammer and large chisel we knock out all of the little oak sections to get us to the bottom of the beam.

After this, the beam bottom is sanded smooth and checked with a template to make sure it will fit to requirement.

The beam is then braced to stop the edges turning in on each other, then sent to a happy customer.

Braces are required to stop the edge of the beam turning in on itself.

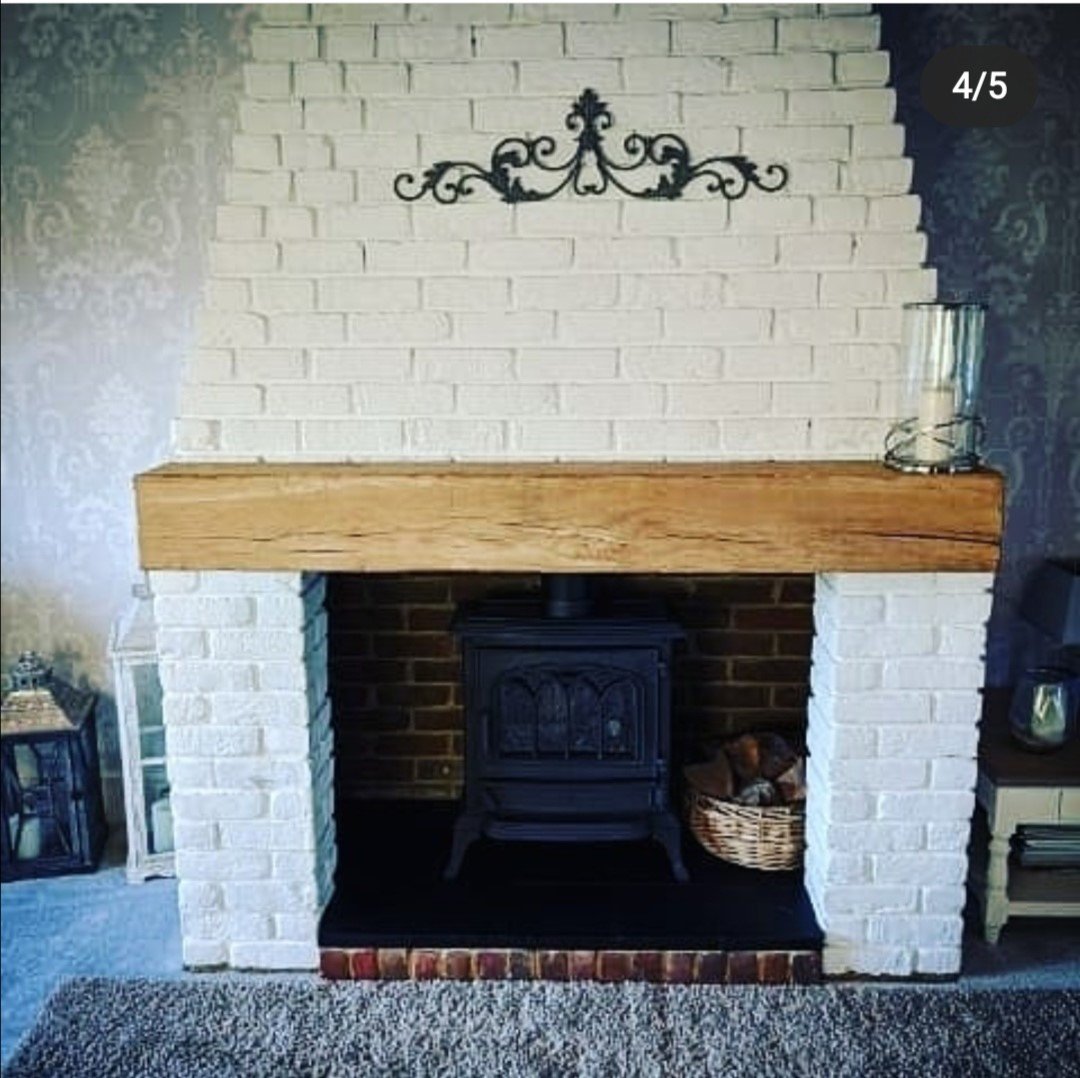

We also semi hollow beams to cover fireplace beams, or lintels that are already there. These are very popular, and are completely bespoke.